Optimum protection

from abrasion

This innovative coating technique involves binding fine ceramic particles firmly onto the textiles, providing protection from excessive wear and tear as well as pilling. The coating can be applied in a variety of attractive designs. The clothing comfort and care properties are not influenced by the coating.

The ceramic coating has been applied to a variety of knitted fabrics. For instance, to elastic warp-knit fabric and coating substrates for laminates. The polyester based fabrics are suitable for transfer printing, and can therefore be printed with individual designs on top of the ceramic coating. The polyamide based materials are suitable for garment-dye, so individual color is also available with ceramic coating designs.

abrasion resistant

abrasion resistant

breathable

breathable washproof

washproof

Further technologies from schoeller® — Show licensing technologies only

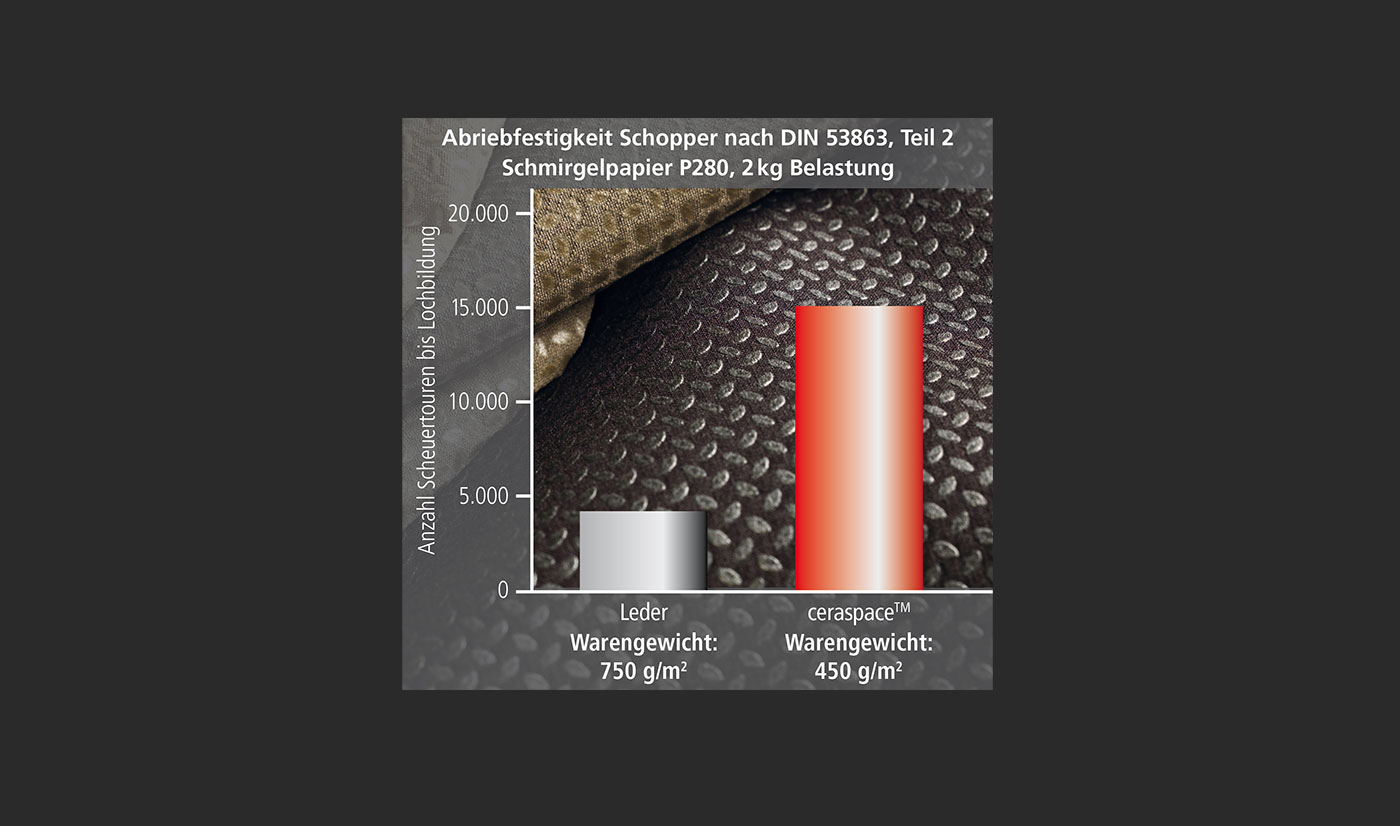

The outstanding ceraspace™ technology from Schoeller owes its outstanding protective properties to a unique composition of special ceramic particles anchored in a polymer matrix. The special ceramic particles are nearly as hard as diamonds and are fi rmly attached as a 3-dimensional coating to the textile. A textile with ceraspace™ performs signifi cantly better than high quality leather in terms of abrasion:

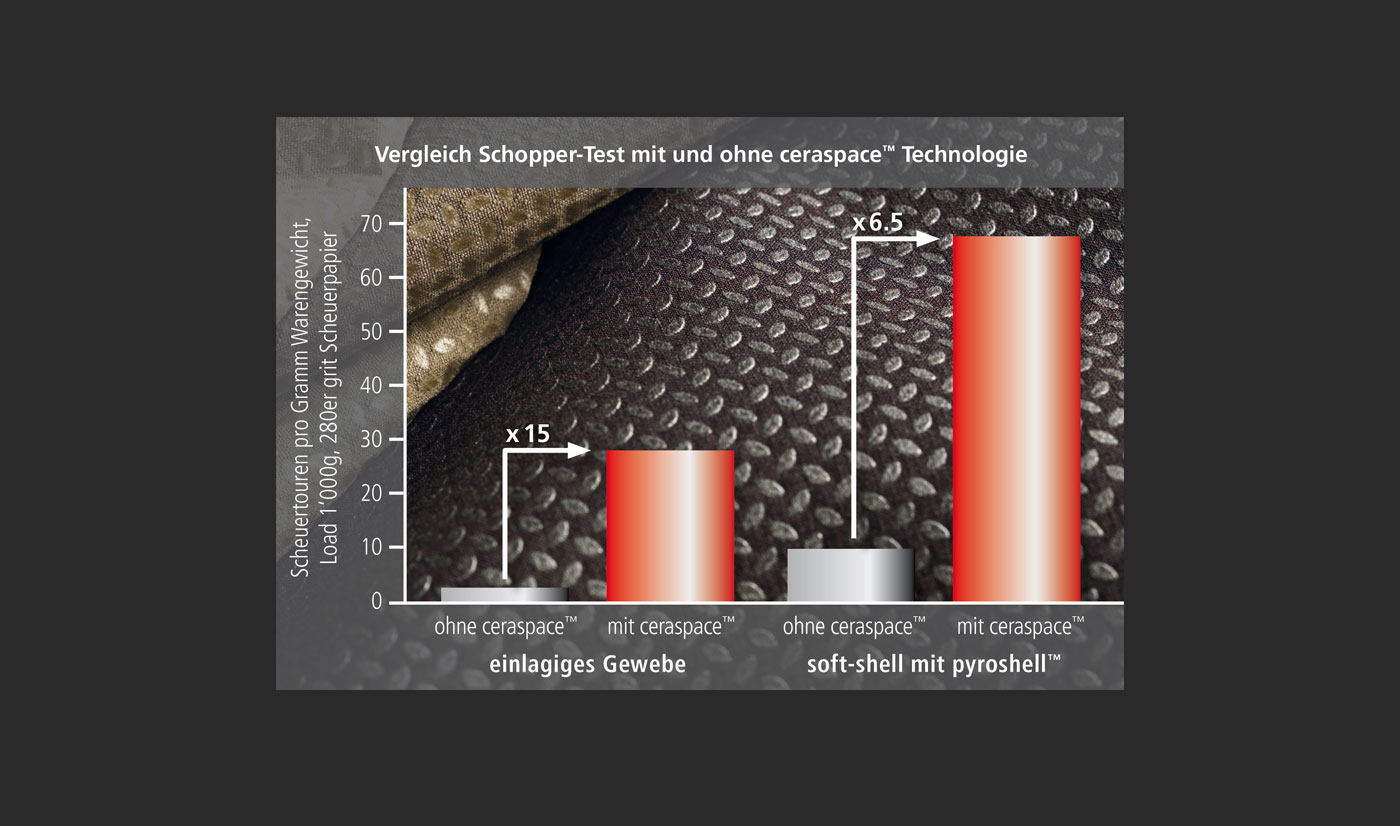

The comparison of two schoeller® fabrics with and without ceraspace™ technology shows, that the abrasion resistance increases signifi cantly thanks to the ceramic coating.

abrasion resistant

abrasion resistant

washproof

washproof

Further technologies from schoeller® — Show licensing technologies only

Read FAQ

Dark-colored textiles absorb both visible and invisible sunlight, meaning both heat and light. In all types of textiles, coldblack® reduces this absorption of thermal radiation. This function is partciularly effective in the case of darker colors. The result is a noticeably better heat management.

In addition, the technologies offer reliable protection from UV rays, which is particularly important for light-colored textiles. A UPF of 30 (minimum) is guaranteed for all colors and textiles, without the feel or look of the product being affected. As a result, textiles with coldblack® can make an effective contribution to protecting against harmful UV rays.

heat protection

heat protection  UV-protection

UV-protection breathable

breathable  cooling effect

cooling effect Further technologies from schoeller® — Show licensing technologies only

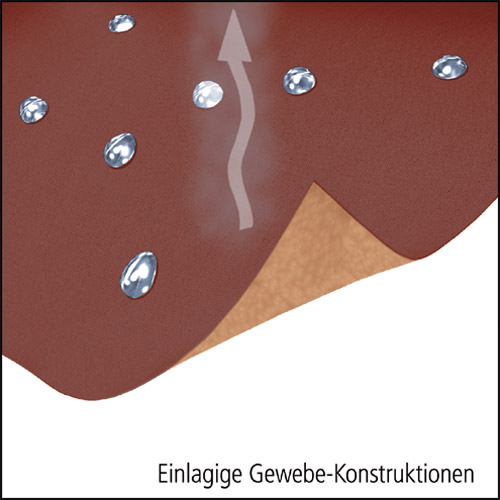

corkshell™ is made of an FSC-certified cork granulate that is a by-product in the manufacturing of wine corks. This natural granulate is pulverized and firmly anchored as a coating in a special process patented by Schoeller.

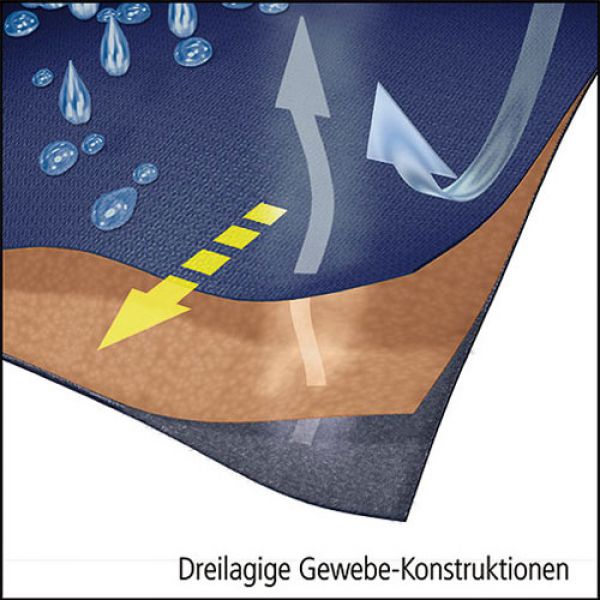

Two corkshell™ options are available:

- Two-layer fabric construction with a cork coating on the inside of the fabric

- Three-layer fabric construction with the cork coating in the middle

All fabric constructions are water and wind repelling, highly breathable and is available in both 2-way and 4-way stretch qualities.

heat retention

heat retention  stretch

stretch water repellent

water repellent  breathable

breathable  wind repellent

wind repellent Further technologies from schoeller® — Show licensing technologies only

schoeller® ecodye makes shorter heating-up phases possible. In addition, the dyeing process improves the product quality. Even with critical nuances and dye combinations, the use of this technology does not negatively impact the evenness of the dyeing.

schoeller®-ecodye ecodye is more than just an environmentally friendly dyeing process which allows savings in time, energy and water. It also reduces the CO2 emissions, improves productivity and offers the greatest possible flexibility in use.

saves time

saves time  saves water

saves water  saves energy

saves energy Further technologies from schoeller® — Show licensing technologies only