Police & Military

Protection

Specialized protective textiles for

law enforcement and military

For example, we offer flame protection with the aid of pyroshell™ technology, wind and rain protection with our c_change™ membrane, ideal moisture management thanks to our 3XDRY® technology, maximum abrasion resistance with our ceraspace™ technology and, most recently, for special units, a suppressed thermal signature – integrated into the specific local camouflage print – with our camoshield™ technology. Combinations of different technologies can also be implemented without difficulty.

Our 7-layer clothing system – from underwear to cold-protection layers – was developed specifically for the military and security sector. With the objective of consistently meeting the challenging demands of frequent physical activity under potentially extreme climatic conditions, extensive testing was performed at the EMPA St. Gallen focused on garment functionality. This testing has guaranteed a perfectly-coordinated clothing system no matter what the weather conditions, with optimum moisture transport and the necessary protection, including from flames and extreme heat.

The modular application of our technologies makes it possible to treat almost every fabric to meet different protection standards. The multinorm fabrics produced by Schoeller can be designed in a targeted and tailor-made manner for required standards or for several standards at the same time.

Our collection comprises products which comply with the following standards, or a combination of same:

- EN ISO 20471 (High visibility)

- EN 1149-5 (Anti-static)

- EN ISO 11611 (Workwear for use in welding and allied processes)

- EN ISO 11612 (Workwear for protection against heat and flame)

- IEC 61482-1-2 (Workwear for protection against electric arcs)

- EN 13034 (Protection against liquid chemicals)

- EN 343 (Rain protection)

With our new Inspire Collection made of 100% polyester – but with the feel of conventional polyester/cotton fabrics – we have created a product with a longer service life, 60% of which originates from recycled PET bottles.

The fact that there is no cotton content reduces the cultivation area and the water required in production. At the end of their life cycle, Inspire fabrics can be completely recycled and processed into PET granulate and staple fibers.

The fact that there is no cotton content reduces the cultivation area and the water required in production. At the end of their life cycle, Inspire fabrics can be completely recycled and processed into PET granulate and staple fibers.

The innovative Inspire Collection consists of a series of different knitted fabrics, woven fabrics and soft-shells, available in EN ISO 20471-compliant high-visibility colors with chemical protection in accordance with EN 13034, or as windproof and waterproof versions in accordance with EN 343 with the recyclable Sympatex membrane.

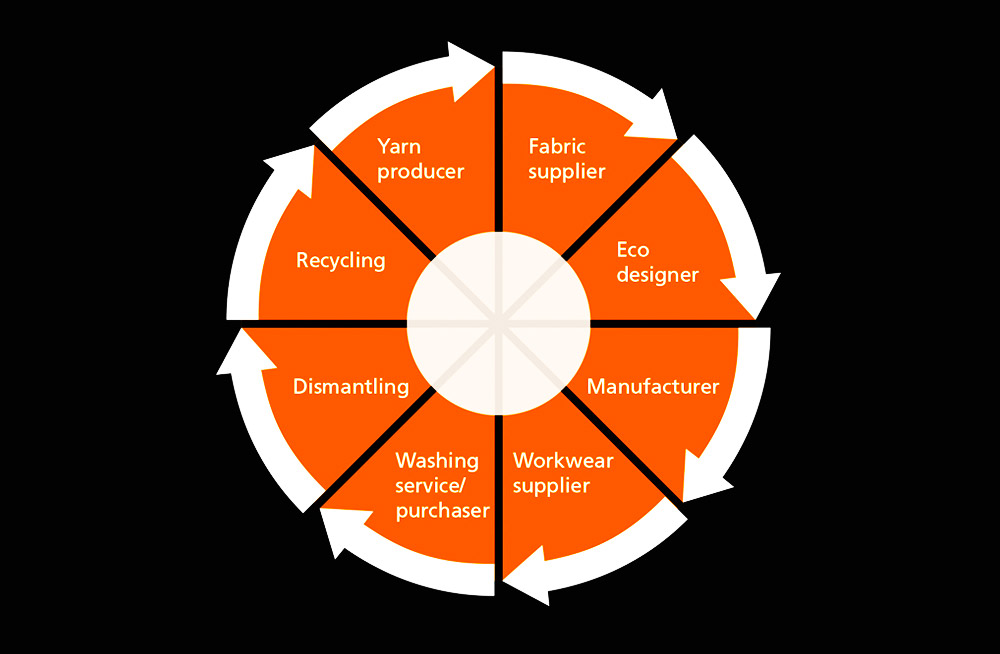

The entire manufacturing and recycling process is avouched by Schoeller and DutchSpirit together with partner operations in Europe.

The entire manufacturing and recycling process is avouched by Schoeller and DutchSpirit together with partner operations in Europe.